उच्च परिशुद्धता वाले औद्योगिक सिरेमिक पिस्टन पंप बड़े पैमाने पर उत्पादन लाइनों के लिए टिकाऊ

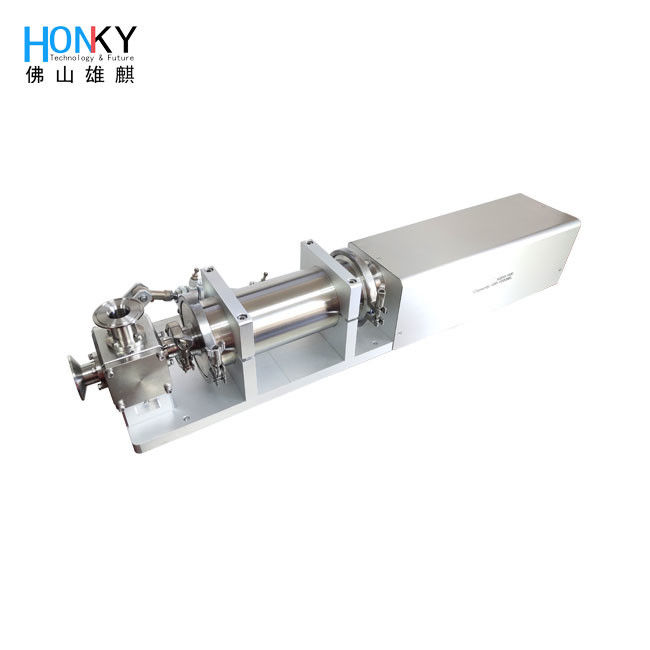

क्रीम पेस्ट जाम भरने के लिए स्वचालित मात्रा समायोजन के साथ सर्वो संचालित उच्च परिशुद्धता सिरेमिक पिस्टन पंप

उच्च परिशुद्धता औद्योगिक सिरेमिक पिस्टन पंप का पैरामीटर

| मॉडल |

XQQGS-12 |

XQQGS-25 |

XQQGS-50 |

XQQGS-100 |

| पंप सिर |

उच्च शुद्धता वाले सिरेमिक |

| भरने की सटीकता |

₹±0.5% |

| भरने की सीमा |

1-12 मिलीलीटर |

2-25 मिलीलीटर |

5-50 मिलीलीटर |

10-100 मिलीलीटर |

| विनिर्माण गति |

0-50 बोतल/मिनट |

| पंप का आकार |

50*15*15 सेमी |

| शक्ति |

AC 220V 50-60Hz 50W |

| वायु दबाव |

0.4-0.6Mpa |

| मोटर का प्रकार |

स्टेप मोटर/सर्वो मोटर |

सिरेमिक पिंपल वायवीय पंप संयोजन एक सटीक सिरेमिक पिंपल डिजाइन को अपनाता है, जो मध्यम और उच्च चिपचिपाहट तरल पदार्थों, क्रीम,और क्रीम (1000-100,000CPS) और कुछ कणों युक्त सामग्री।

उच्च परिशुद्धता औद्योगिक सिरेमिक पिस्टन पंप की विशेषता

खाद्य ग्रेड सिरेमिक पिस्टन भरने पंप खाद्य और पेय उद्योग के लिए एक सटीक समाधान है। यह विभिन्न उत्पादों को संभालता है - सिरप, सॉस, शहद, पेस्ट - असाधारण सटीकता के साथ, स्वच्छताऔर विश्वसनीयता, संवेदनशील, उच्च मूल्य वाले सूत्रों के लिए आदर्श है।

1. खाद्य एवं पेय उत्कृष्टता के लिए परिशुद्धता इंजीनियर

इसके कोर रोटरी-टू-लाइनर तंत्र में खाद्य ग्रेड आस्तीन में एक सिरेमिक पिस्टन का उपयोग किया जाता है; स्ट्रोक की लंबाई पंप सिर कोण के माध्यम से समायोजित की जाती है। यह सटीक, दोहराए जाने योग्य विस्थापन सुनिश्चित करता है,पारंपरिक पंपों की धड़कन और असंगति को समाप्त करना.

कोमल व्यवहार

सुचारू घूर्णन से मधु, इमल्शन और फल के पल्स की गुणवत्ता बरकरार रहती है।

उच्च परिशुद्धता

±0.5% सटीकता और ±0.1% दोहराव उत्पाद अपशिष्ट को कम करता है, उच्च मूल्य वाले अवयवों के लिए लागत को कम करता है।

2स्वच्छता, सुरक्षा और स्थायित्व के लिए निर्मित

खाद्य-अनुकूल सामग्री से बना, यह साफ करने में आसान है और कठोर खाद्य उत्पादन वातावरण के लिए टिकाऊ है।

सिरेमिक पिस्टन

पहनने के लिए प्रतिरोधी, निष्क्रिय, और अति चिकनी, यह चिपकने का विरोध करता है और सफाई को सरल बनाता है - यहां तक कि शहद या चॉकलेट के लिए भी।

खाद्य श्रेणी के भाग

316L स्टेनलेस स्टील और पीईईके/पीटीएफई गीले घटक अम्लीय/लवण खाद्य पदार्थों के लिए संक्षारण प्रतिरोध प्रदान करते हैं।

3उत्पादन लाइनों में निर्बाध एकीकरण

यह पंप सिर्फ एक घटक के रूप में नहीं बल्कि एक पूर्ण भरने की प्रणाली के रूप में कार्य करता है।

स्मार्ट कंट्रोल

त्वरित व्यंजनों, डेटा लॉगिंग और सिंक्रनाइज़ेशन के लिए एनालॉग/डिजिटल (RS485/Modbus) के माध्यम से पीएलसी/एससीएडीए के साथ इंटरफ़ेस।

आसान रखरखाव

तेजी से विघटन सीआईपी/एसआईपी का समर्थन करता है, डाउनटाइम को कम करता है और स्वच्छता मानकों को पूरा करता है।

उच्च परिशुद्धता औद्योगिक सिरेमिक पिस्टन पंप का उत्पाद प्रदर्शन

आवेदन क्षेत्र

- ओडीएम और ओईएम उत्पाद डिजाइन

- स्वचालित विनिर्माण लाइन डिजाइन

- कॉस्मेटिक उत्पाद पैकेजिंग

- फार्मास्युटिकल और बायो-रिएजेंट उत्पाद पैकेजिंग

- प्रयोगशाला तरल पदार्थ वितरण

- लिथियम बैटरी तरल पदार्थ वितरण

- सिरेमिक पंप और सिरेमिक पंप भागों का डिजाइन

- अन्य क्षेत्र की सामग्री भरना

प्रश्न और उत्तर

प्रश्न: क्या आप OEM सेवाएं प्रदान करते हैं, मैं विदेश से एक वितरक हूं?

एकः हाँ, हम दोनों OEM सेवाओं और तकनीकी सहायता की पेशकश कर सकते हैं. आपका स्वागत है अपने OEM व्यापार शुरू करने के लिए.

प्रश्न: बिक्री के बाद की सेवा के बारे में क्या?

उत्तर: मशीन की 1 वर्ष की वारंटी है। और हम आजीवन बिक्री के बाद सेवा और तकनीकी सहायता प्रदान करते हैं।

प्रश्न: आपकी स्थापना सेवाएं क्या हैं?

एकः स्थापना सेवाएं सभी नई मशीन खरीद के साथ उपलब्ध हैं। हम उपयोगकर्ता मैनुअल और वीडियो मशीन की स्थापना, डिबगिंग, संचालन का समर्थन करने के लिए प्रदान करेगा,जो आपको इस मशीन का अच्छा उपयोग करने का तरीका बताएगा.

प्रश्न: मशीन मॉडल की पुष्टि करने के लिए किस जानकारी की आवश्यकता होगी?

A:

- भौतिक स्थिति

- भरने की सीमा

- विनिर्माण गति

- उत्पादन प्रक्रिया के लिए आवश्यकताएं

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!